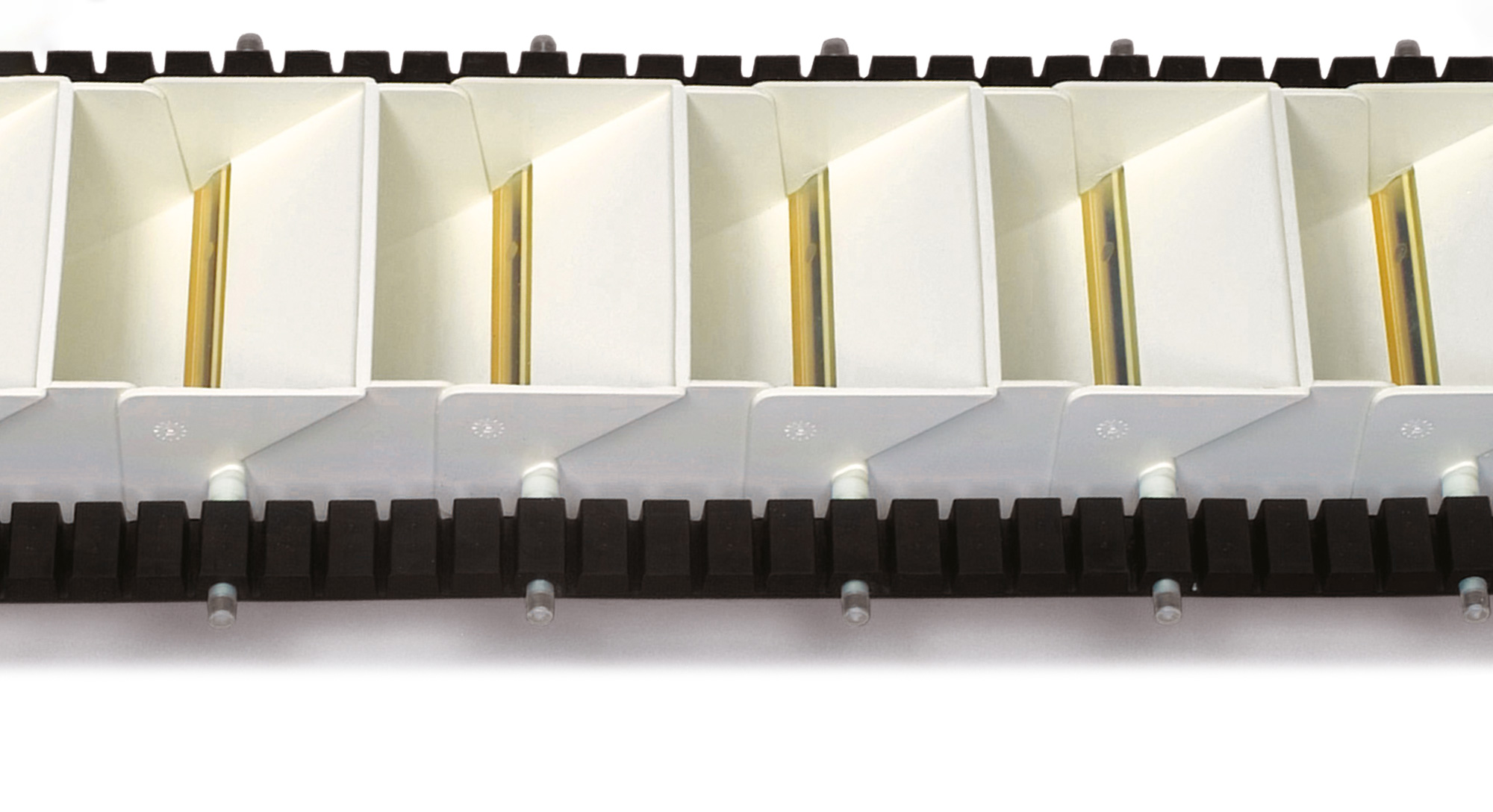

WIESE pendulum bucket and continuous bucket conveyors can be supplied with a variety of housing options. There are suitable designs for virtually every requirement. From the gas-tight casing version made from sheet metal to the open tubular framework for special hygiene requirements, everything is possible. We distinguish in this context between the following 4 variations:

Casing

1. Standard casing, self-contained sheet design

- Favourable standard

- Self-supporting

- Maintenance hatches all round

- Painted steel or stainless steel

- Optionally also available dust-tight

2. Standard casing with removable side parts

- Like standard sheet housing, however with large removable side pieces

- Easier cleaning

3. Open tubular framework

- Welded construction made from stainless tubular steel

- No horizontal surfaces

- Ideal for wet cleaning

- Quickly removable hand protection device with panelling made of polycarbonate or stainless steel

4. Gas-tight casing

- Special construction

- Customised for each application

- For inertisation with inert gas

With all versions, we attach great importance as standard to good accessibility for maintenance purposes. Each bucket conveyor includes drawers under drop-off points and corner stations that can also be used from both sides. Undercuts are reduced to a minimum to avoid product deposits.

Painted or powder-coated regular or rust-free steel are used as materials for our casings. For rust-free steels, we use 1.4301 (V2A) as standard, but for more rigorous demands in the chemical, pharmaceutical or food industry 1.4571 (V4A) or similar can also be used. Other materials are available on request, however.

The structure of the casing is always modular. This gives you the option of changing the layout of the bucket conveyor at any time. Even after many years, we can supply the casing segments and components needed for your system.

Extras such as viewing windows or connections for extraction units can be accommodated for all casing versions.