Detectable buckets

WIESE is constantly researching alternative materials for product-contacting components.

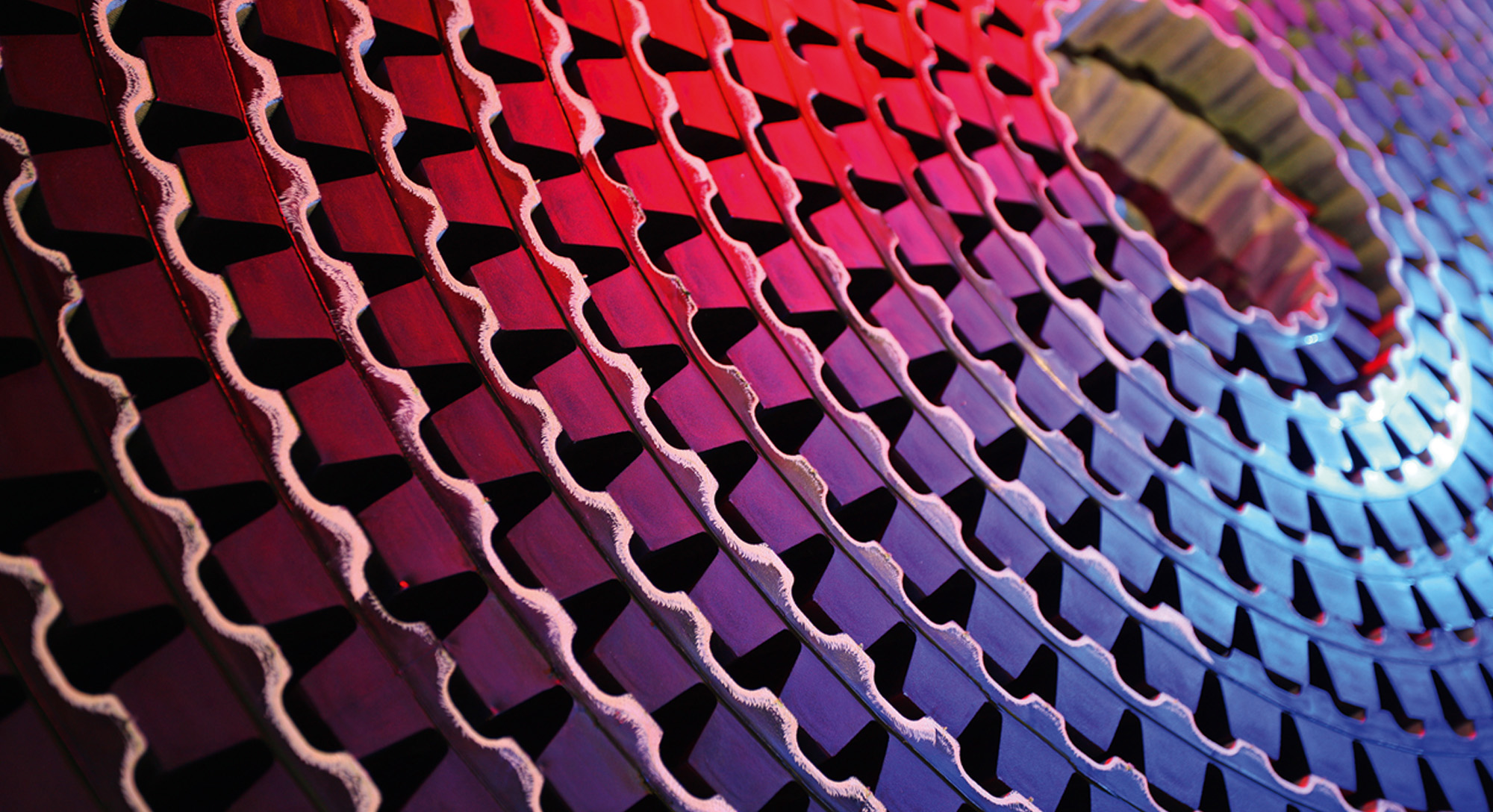

Many of our pendulum and continuous bucket conveyors are supplied to the food industry. For this reason - in addition to easy cleaning - the safety of the product being transported is the main focus. It is important that the bucket material used can be detected in the product stream in case faults cause material to break away from the buckets and fall into the product stream. In the past, attempts were often made to do this using coloured plastics.

WIESE has been using buckets made from detectable plastic with food-safe approval for over 10 years with great success.

To test the detectability, small plastic particles (<Ø 5mm) were hidden in the end product packagings. These tests yielded very satisfactory results.

Many of our customers subsequently standardised the use of detectable plastics for product-contacting parts. This ensures that no contaminated products are able to make their way to supermarket shelves.

What is the advantage for the customer?

- Product safety

- Reduction of potential product contamination and recall campaigns

- Potential contamination can be detected with existing magnetic detectors and separators

Material properties

- Material is food-safe as described by FDA and EU 10/2011 regulations and EC 1935/2004

- Outstanding physical properties

- Biologically inert

- Not chemically reactive

- Non-toxic

- Can be used with greasy foodstuffs

Detectable and removable

- It is possible to remove particles up to a small size, depending on the separator, from free-flowing powders

- Particles up to a minimum size of 5 mm in diameter can be detected in ready-packed product units, depending on the magnetic detector

- Plastic that can be detected based on metallic and magnetic properties